Perrier: safety, efficiency, performance, aiming for Industry 4.0

The history of Perrier, one of the world's leading suppliers of sparkling mineral water, dates back more than one century when in 1863, Sir John Harmsworth met Dr Perrier and decided to rename the Les Bouillens spring in Vergèze he had bought in the south of France in his honour. The mineral water began to be marketed in its iconic green bottle first in Great Britain and then in France. It was promoted as the “champagne of table waters” and its prestige grew exponentially over the years.

The French brand was acquired by the Nestlé Group in 1992 to exploit its great potential and expand its global reach even further. Today, more than a billion bottles are sold in over 140 countries each year.

Nestlé Waters is expanding the Vergèze bottling plant to meet the increasing market demand and boost the production capacity of the factory while ensuring the highest degree of plant sustainability. With these goals in its sights in 2018, Perrier invested over €200 million in the Perrier Cap 2020 Global Plan. The project was an ambitious one: to produce more than 2 billion bottles a year while cutting CO2 emissions by 2,500 tonnes.

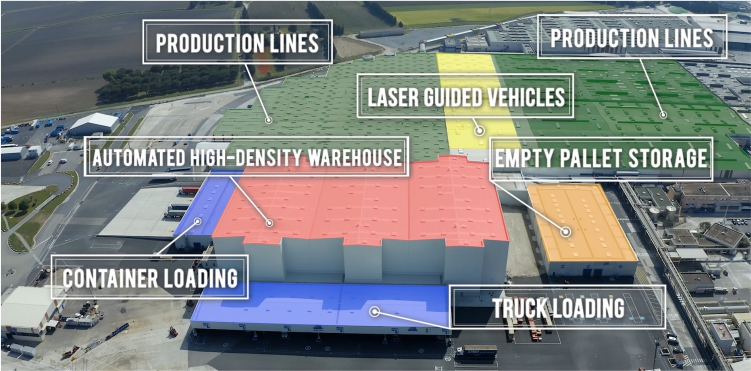

The decision to invest in reliable and flexible automated intralogistics solutions was one of the strategic elements of the project. Our Group was by the side of Perrier along the digitisation process of the production plant by offering targeted studies, identifying the many strengths and aiming at the total integration of all operations using innovative technologies, such as automatic laser-guided vehicles, high density warehouses, shipping management and planning and the SM.I.LE80 software for coordinating and supervising the performance of the entire plant in real time, guaranteeing full product traceability at all stages.

"E80 Group cooperated with us throughout the project from design to implementation”, says Xavier Salaun, Project Logistics Manager. “Our two companies shared their expertise, vision and challenges to meet all needs. The result is the brainchild of a true partnership and genuine teamwork.”

The result led to the development of an extremely flexible solution for storing around 45,000 pallets in-house in an automated high density warehouse, managing differentiated shipments and, more importantly, coordinating flows safely and efficiently.

The decision to invest in an AVS/RS SmartStore warehouse offered significant advantages in terms of potential and stored pallets density within the same volume and storey accessibility by arranging nine levels in an area of just 12,000 m² to meet the economic, structural and technological requirements of Perrier.

All lines are equipped with a robotic stretch wrapping system that guarantees product integrity and high pallet stability, in addition to considerable savings in the amount of plastic film employed. The automatic laser-guided vehicles can handle up to 360 pallets per hour and integrate all operations, conveying the finished products from production lines to the end-of-line and from here to the automatic warehouse. Last but not least, two empty pallet inspection systems capable of inspecting about 400 pallets per hour are essential to ensure efficient and safe operations. Laurent Capel, Supply Chain Director, underscores the relevance of this solution: “Controlling the quality of our wooden pallets on the production lines allowed us to improve the efficiency of our end-of-line palletisers.”

The partnership was characterised by shared values from the beginning. “The concepts of sustainability and safety are fundamental for Nestlé”, Xavier adds. “This is why we chose the E80 Group solution because it offered the advantages of reliable safety systems on LGVs, lithium-ion batteries for reducing the carbon footprint of our production and a fully automated system.” Our LGVs are equipped with safety systems that go beyond those required by current regulations to ensure the highest levels of safety for people and products throughout the plant. Every LGV is powered by lithium-ion batteries: a technology for longer battery life, faster charging times and lower running costs.

Finally, our Group supports Perrier with a 24/7 digital support service to ensure continuity, efficiency and constant performance over time. “For Nestlé, after-sales service is a priority when choosing a supplier”, declares Adrien Riboullon, Maintenance Manager. “The E80 Group solution with its after-sales service, help desk, 24/7 availability and all related services reassured us so we knew our choice was a good one.”

The Perrier plant is the real result of collaboration without weak links with our Group to create a single integrated and sustainable industrial solution, capable of guaranteeing a superior level of process reliability, ensuring full product traceability, reducing waste and guaranteeing optimal service levels to consumers.

"This technology has revolutionised logistics and maintenance. This is a major development for all the people working in the industry today.” - states Xavier Salaun.