Roto-Cart: technology, quality, and distribution to make the difference in the tissue market

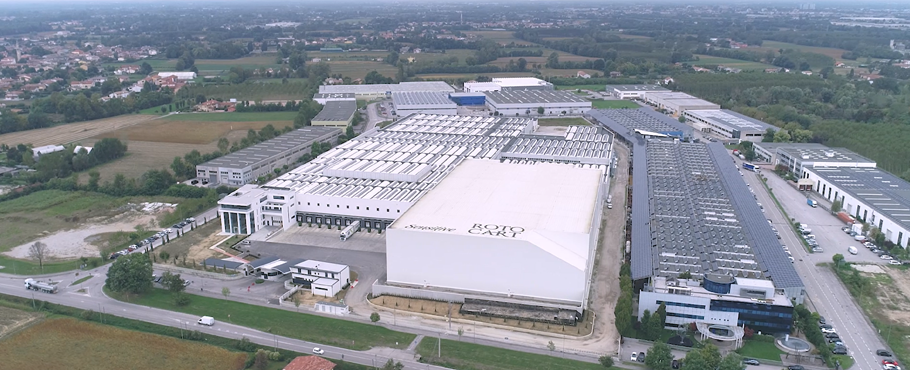

Established in 1981 by the Gelain family to innovate the production methods of the tissue sector with trail-blazing technologies, Roto-Cart soon made a name for itself in the domestic and international markets as a manufacturer of high-quality toilet paper, kitchen paper rolls, napkins, and AFH (Away From Home) products for retail and wholesale.

Technology, quality, and distribution are the three pillars of the company's activities to offer premium products to consumers while pursuing ambitious sustainability goals. The company is FSC-certified, guaranteeing that products come from responsibly managed forests and supply chains, and is also Ecolabel-certified, attesting the low environmental impact of production processes. It is precisely this focus on eco-friendliness that drives Roto-Cart in the continual search for increasingly advanced, innovative, and sustainable solutions. E80 Group is the perfect partner to bring the projects of Gelain into fruition, including the build of a fully integrated factory in Castelminio, Treviso. Strong of its expertise in greenfield and brownfield plant development gained over the years with 900 LGVs, 600 robotic lines, and 200 robotic wrappers installed worldwide, E80 Group accepted the challenge in 2016. The Roto-Cart system is on the cutting-edge today in terms of integration and flexibility from raw materials entry, palletizing and warehouse management - all fully interacting with the customer's ERP system - to the loading of the finished product on transport means.

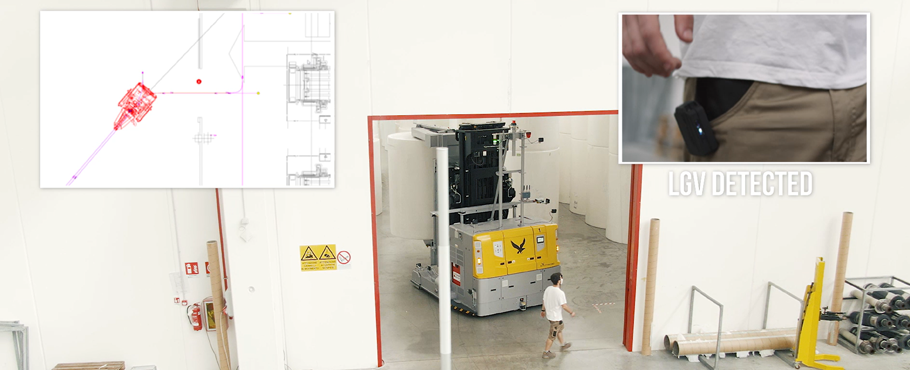

Automated raw material management with a Unicorn LGV

The intralogistics flow starts from the entry of raw materials in the plant, where the paper reels are handled by Unicorn, the next-generation laser-guided vehicle (LGV) specifically developed to lift, move and deposit jumbo rolls weighing up to 5 tons and of 3 meters in diameter both vertically and horizontally. Patented by the E80 Group, this LGV prevents damage to the paper by automatically inserting two chucks inside the core and avoiding any contact with the external surface. Furthermore, the technology allows the rolls to be placed directly in contact with each other to optimize storage by up to 7% and drastically reduce the so-called “chimney effect” in case of fire.

Increasing safety within the plant is a key element. All our LGVs, including Unicorn, are equipped with extra technological systems than those required by international standards. For instance, our Group has recently patented SmartDect, an anti-collision device that innovatively employs Ultra-Wide Band technology to increase the ability of the LGVs to detect the position, speed, and direction of movement of operators and other vehicles in the surrounding area. This reduces and often even eliminates the risks associated with potentially dangerous situations deriving from incorrect or unpredictable behaviors.

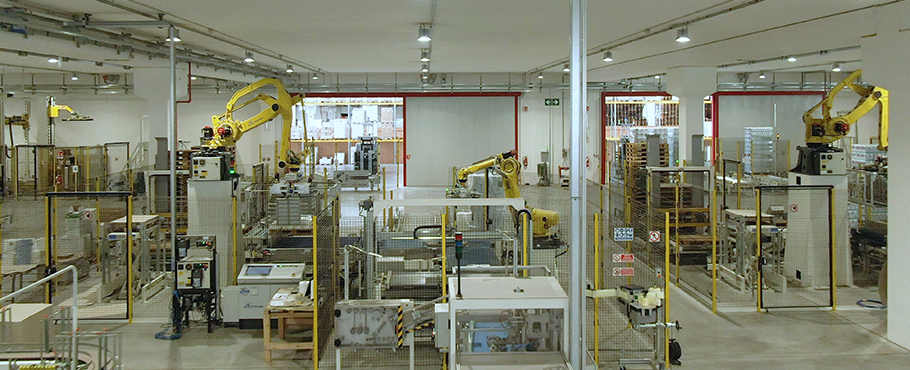

Innovative and reliable end of line with state-of-the-art robotics systems

At the end of the converting and finished product manufacturing lines, our Dragon palletizing islands, specifically designed for the tissue industry, offer high performance in terms of speed, precision, and efficiency. The product is handled gently to preserve its integrity. The LGVs transfer the pallets to the wrapping island, where Silkworm wraps 94 pallets per hour, guaranteeing load quality and stability. Furthermore, it contributes to increasing the overall sustainability of the plant by reducing both the use of plastic material and the energy consumption thanks to a lower number of wrapping turns needed.

Superior performance guaranteed by SmartStore automated high-density warehouse

This system offers high density warehousing of finished goods by maximizing storage capacity per unit area. It is an ideal solution for high volumes of consumer products. SmartStore also offers significant savings in terms of energy and maintenance costs by implementing regeneration functions for the lithium-ion batteries that power the satellites and shuttles to the benefit of the overall plant safety.

SM.I.LE80: full Smart Factory integration

Our software platform manages and supervises all operations, synchronizing systems and intralogistics flows within the factory. SM.I.LE80 communicates with production lines, palletizers, wrappers, coordinating the handling of products with LGVs, storage in the warehouse, up to the organization and optimized planning of transport to end customers. By communicating with the customer's ERP, our software assigns the missions to the LGVs to transfer the pallets from the production lines or from the warehouse to the shipping area. For the picking activities, the pallets can be transferred from the LGVs over an upper level where new pallets with different codes are formed and then transferred to the staging area.

SM.I.LE80 monitors the performance of the entire solution in real time, ensuring full product traceability, maximum efficiency and safety.

Roto-Cart and E80 Group, a partnership capable of innovating with the aim to achieve superior levels in terms of efficiency, safety, and sustainability.

Roto-Cart 2021 from E80 Group on Vimeo.