Virto Group: efficiency, safety and high productivity rate at -25° C

How can intralogistics operations be managed efficiently at more than 20 degrees below zero?

Discover how E80 Group integrated systems improved performances at Virto Group deep-freeze warehouse.

The partnership between Virto Group and E80 Group

How can intralogistics operations be managed efficiently at more than 20 degrees below zero?

The automation project of Virto Group, one of the leading companies in the production and distribution of frozen products for the food industry, food service, and supermarket chains, serves as a leading example of Smart Cold Storage Warehouse.

Let’s start from this video:

E80 Group & Virto_ESsubEN from E80 Group on YouTube.

The partnership between Virto Group and E80 Group

Founded in 1984 in Azagra, Navarra, the Spanish company in forty years of business has opened 22 centers in 10 different countries offering an increasingly wide range of frozen food products worldwide.

The Group's path of growth and evolution has always been guided by the pursuit of innovation and sustainability, which is inspired by the Virto Total Quality Model: knowledge, ideas, people, effort, and passion are the fundamental qualities to guarantee food safety and respect for the environment. The automation and integration of its food storage and preservation operations are the trump cards that enable Virto Group to achieve these goals and meet the increasing demands of the Market every day, choosing our Group as a partner with which to meet these challenges.

“Automation is a way to optimize responsiveness, increasing productivity and reducing costs. It also standardizes processes and guarantees safety for all team members. - says Juan Virto, Industrial Director at Virto Group - Installing this type of solution satisfies the environmental and personal aspects of the Group's sustainability strategy”.

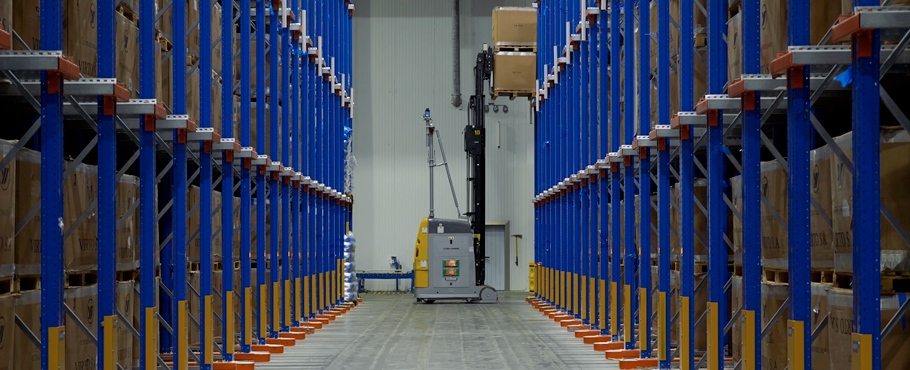

Virto Group’s deep-freeze warehouse

In order to cope with high demand, it is fundamental for the Spanish group to be able to maintain a high uptime rate, along with accurate inventory management and order fulfillment; all this at 25° C below zero.

Thanks to integration by E80 Group's laser-guided vehicles (LGVs), ingredient handling and storage operations within the deep-freeze warehouse are efficient, safe, and constantly coordinated and supervised by our Group's proprietary software platform SM.I.LE80 - Smart Integrated Logistics.

In fact, the entire LGVs portfolio, along with the high-density automated warehouses AVS/RS and AS/RS, is developed to work at temperatures as low as -26° C. In addition to the mechanical components of the vehicles, which are specially designed for ultra-frozen environments, another key factor is the performance of the lithium-ion batteries with which the LGVs are equipped. The latter, in fact, are developed to work down to -30° C thanks to thermal insulation and heating systems improving the overall performance of the plant.

Digitalization as a key asset for the overall result

The digitalization operation has translated into tangible results for Virto Group:

- Productivity has improved due to increased plant availability: LGVs are able to manage the plant 24/7, 365 days a year, responding to the number of flows and missions needed to meet Virto's demand.

- Maintenance work has decreased by 90%, ensuring greater operational continuity.

- Electricity consumption has been reduced by 80%, marking an important milestone toward the Group's sustained environmental commitment. “The synergy between the two companies ensures us reliability, experience and knowledge of hardware and software solutions. Technology evolves very rapidly, and having a partner company with the ability to adapt to the environment and the new challenges of the future gives us greater confidence and a broader vision in the search for improvements and solutions." - Juan Virto concludes.

Curious about other examples of integrated automation applied to cold storage industry and warehouses?

- Read the success business story of innocent refrigerated warehouse, in The Netherlands

- Get to know the general benefits of automated storage systems

- Watch this video of a customer’s cold chain storage solution:

Deep-Freeze Storage & Cold Chain_EN from E80 Group on YouTube.