Distribution centers and picking solutions: the drive for change beyond Industry 4.0

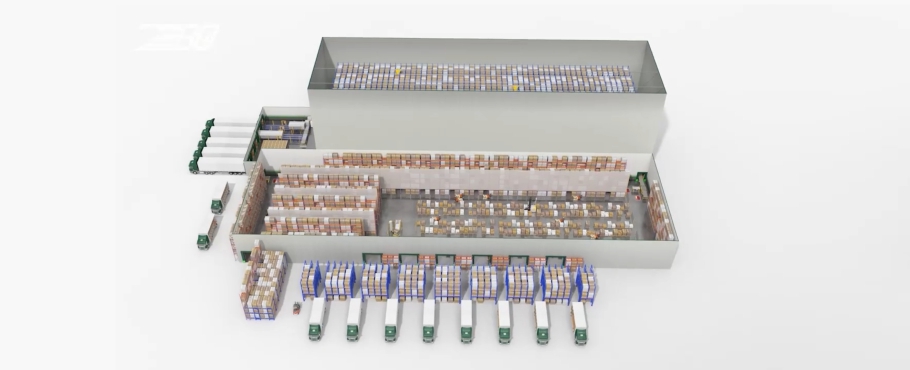

The automated management of the distribution center (DC) has a positive influence not only on internal intralogistics operations but also on the level of service offered to end consumers. Developing automated and integrated solutions is essential to achieve greater system efficiency, 100% operations reliability, and significant productivity increase while maximizing safety for personnel and ensuring the total integrity of products and facilities.

All operations, either automated or manual, from material reception to the shipping of orders to customers, are managed and controlled by our SM.I.LE80 software platform that communicates in real-time with the customer’s systems and ERP, guaranteeing total traceability.

Just-in-time reception of raw materials and automatic pallet inspection

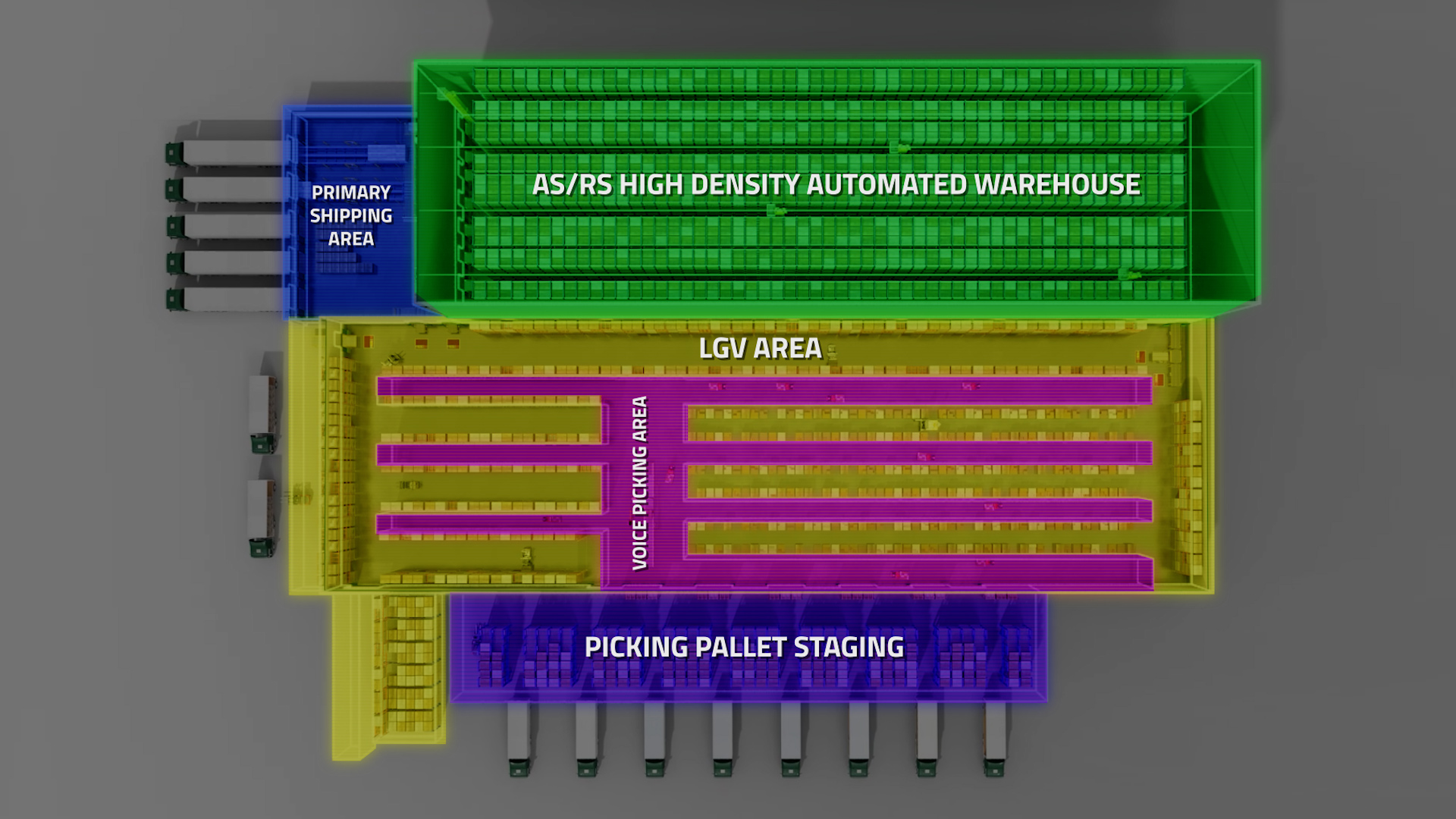

The finished product pallets are unloaded automatically by automated laser-guided vehicles (LGVs) at the entrance of the distribution centre. This optimises truck downtime, reducing costs and CO2 emissions. The pallets are thoroughly inspected by Pallet Shape Control which checks compliance with requirements. This ensures maximum operator safety and total product integrity during storage operations.

Reliable and efficient storage in the high-density automated warehouse

After having been checked for compliance, the pallets are transported by LGVs to the inlet of the Crane Store automated high-density warehouse. This AS/RS solution, which can reach a height of up to 40 meters, provides up to five times more storage density per unit area than conventional solutions.

By using single, double, or multi-depth automatic product handling devices, the warehouse offers maximum selectivity and reliability with optimum performance for distribution centers managing high numbers of SKUs.

High-performance picking solution

After the DC has received the customer orders, the finished product pallet is taken by LGVs from the AS/RS and transported into the picking area.

Thanks to the synchronization between the SM.I.LE80 software and the customer's ERP, the LGVs arrange the products according to their stability and rotation speed applying a very precise order simulation system.

This minimizes the footprint. More in detail, the floor space is divided into two areas. The low-rotation SKUs are managed dynamically by LGVs according to the received shipping orders, while high and medium-rotation SKUs are placed on the floor for faster access by operators.

When all the SKUs are available in the picking area, thanks to the pallet repositioning by LGVs, SM.I.LE80 communicates through the voice picking system the orders to the operators, who create the mixed pallets.

The picker then transports the pallet to the stretch wrapping and labeling system.

The automated picking solution is scalable and flexible to improve the operator's productivity by optimizing time and reducing errors. It eliminates bottlenecks and reduces long-term maintenance costs.

Automated and synchronized shipping

Finally, the SM.I.LE80 software platform organizes shipping orders according to the various market channels and customers' priorities.

Our software ensures that shipping orders are seamlessly integrated into our system. By communicating with the customer's ERP, the finished products ready for shipping are transferred in real-time from both the warehouse and the picking area.

Highlights

- Integration and sustainability: As a whole, integrated and automated management of the distribution center ensures on-time, error-free product deliveries to customers with major improvements in sustainability.

- Customer service: The excellent performance of the solution is also consistently ensured over time by our on-site service and 24/7 customer service offering dedicated support to protect customers' investment over time.

- Safety: Safety is a fundamental issue for the E80 Group. All our systems are equipped with additional protection devices to those required by the regulations in force and guarantee that all operations are carried out in full safety.

Distribution Center and Picking Solutions from E80 Group on Vimeo.