AUTOMATION AND INTRALOGISTICS 4.0: THE FUTURE OF DISTRIBUTION CENTERS

In an ever-evolving world, distribution centers are facing increasingly complex challenges. The growing market competitiveness and the rising customer demand for faster and more efficient service are putting decision makers to the test. In this context, relying on one trusted partner for supply chain integration and the digitalization of processes plays a critical role.

CURRENT AND FUTURE CHALLENGES

The logistic automation challenge in distribution centers.

Global distribution centers (DCs) are currently facing an exponential growth of challenges in the logistic sector.

Why? In short, due to increased market competitiveness and a rising demand for higher service levels from customers. The trends clearly show an increase in the number of products with faster and more efficient time-to-market, along with the proliferation of new distribution channels, including dark stores and innovative last-mile delivery solutions.

Integrated supply chain systems and the digitalization of intralogistics processes play a fundamental role in the success of businesses. Facing this challenge is not merely about adapting; it requires a veritable transformation driven by rapid technological evolution. Sustainability also plays a key role among the challenges—a crucial objective for successful businesses that aim to optimize resources, reduce waste and maximize safety.

How to optimize the management of a distribution center? Read more here.

CURRENT AND FUTURE BUSINESS RISKS

The risk of losing competitiveness in the face of automation.

The main risk during this transformative phase is the rapid loss of competitiveness. In the past, the larger brand prevailed over the smaller one, but nowadays, speed is the key to success. Fast outpaces slow. DCs that rely on manual and non-digitized processes risk being overwhelmed by the ever-increasing and pressing demands of the market, resulting in a loss of the required service level. Infrastructure, technological, and socio-environmental limitations mean a change in perspective is a necessity. A tangible example is the growing difficulty companies face in finding personnel to handle exhausting, repetitive, and low-skilled tasks. In this perspective, customized logistic automation projects become indispensable for every company.

Considering implementation times that range from twelve to thirty months, depending on the type and complexity of the project, postponing the decision to evolve to a future time poses a real risk to the survival of every distribution center.

Read the success business story of Visy distribution center, in Australia.

TECHNOLOGY TO MITIGATE RISKS

Technological development is the backbone of this revolution. What was once considered a luxury has become an indispensable necessity today and in the future. Custom automated solutions, combining cutting-edge software and robotic automation, emerge as the winning path to medium and long-term business success.

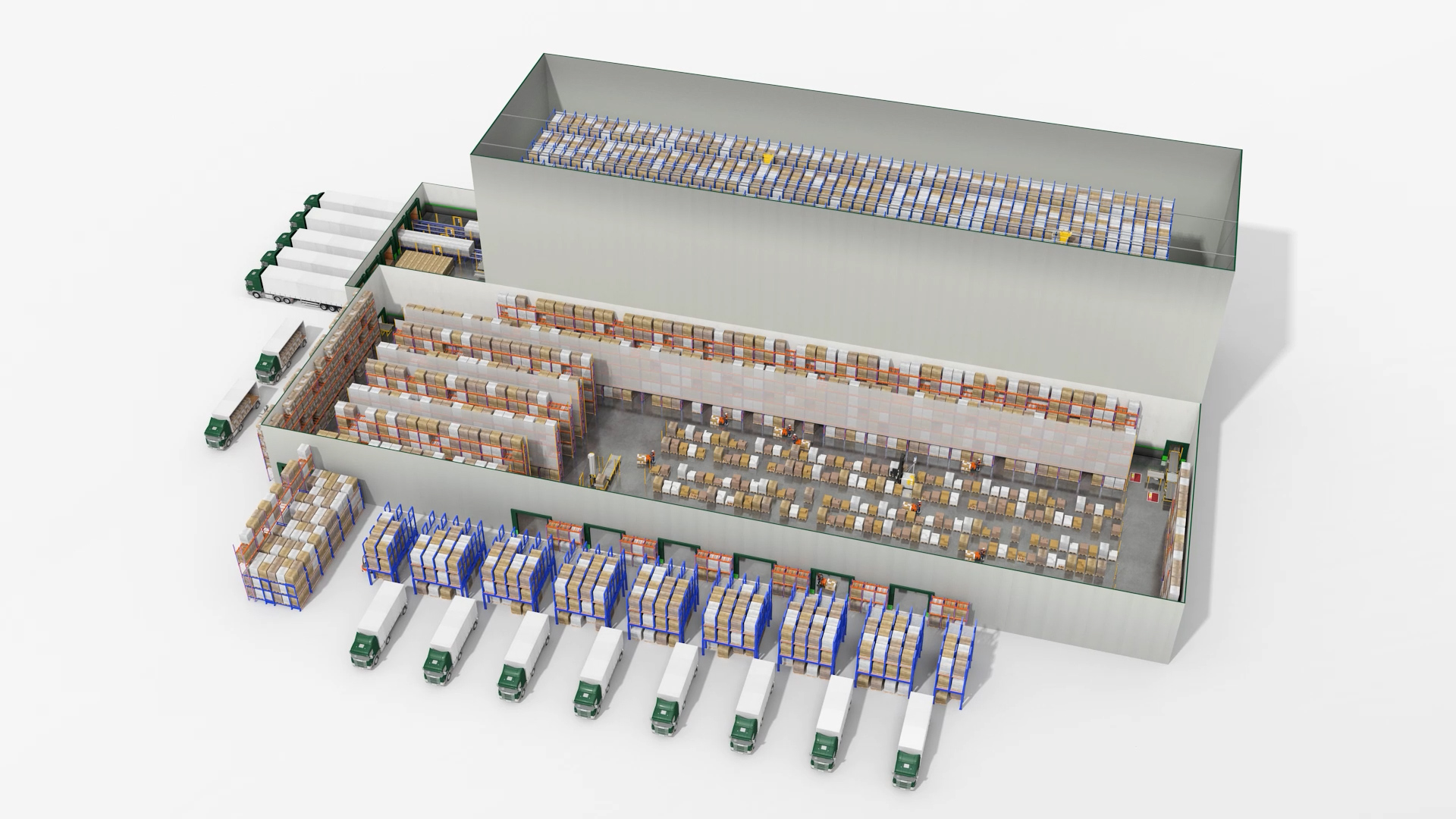

E80 Group has been committed to conducting technological research to enable automation and integration of the majority of operations in Distribution Centers for years, both in existing facilities (brownfields) and newly created ones (greenfields), ensuring efficiency, speed, safety, and traceability of all movements within the DC in a flexible and scalable manner. In an era where timely responses are crucial, flexibility and scalability become indispensable characteristics for Distribution Centers, inherently front-end and, therefore, necessarily adaptable to rapidly changing customer needs.

THE TECHNOLOGICAL FUTURE AND CHALLENGES TO FACE

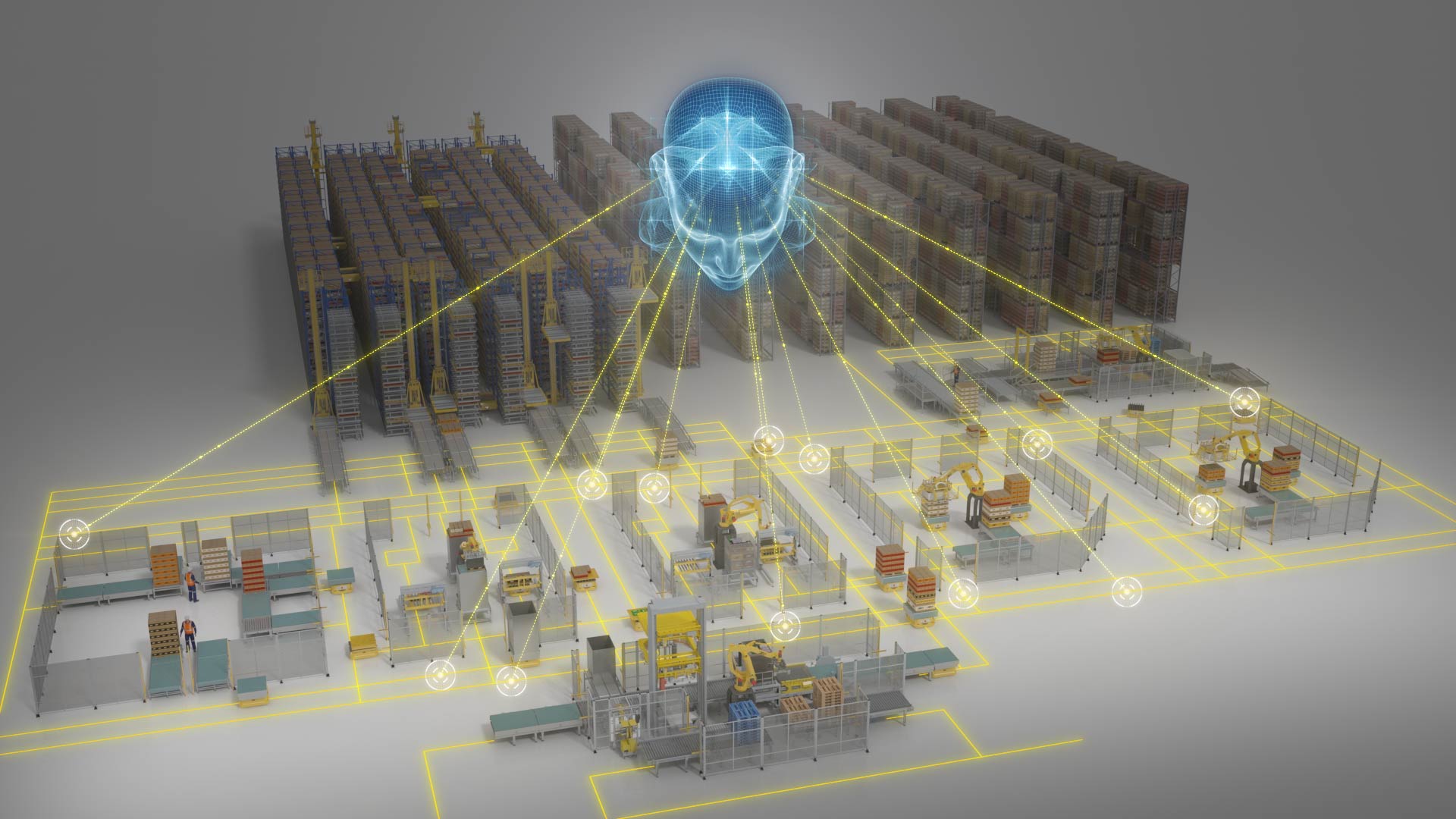

The rapid development of artificial intelligence and software based on neural networks will accelerate the transformation of the near future. These tools will analyze vast amounts of data with the goal to make the best strategic decision. In this scenario, investing in automatic systems is a winning strategy as it allows for complete digitalization of data collection, enabling us to measure in order to improve.

Read the success business story of Ypê distribution center, in Brasil.

E80 GROUP'S SOLUTIONS FOR THE DISTRIBUTION CENTERS OF THE FUTURE

The strength of E80 Group lies in its proprietary software platform, which synergistically integrates all intralogistics processes, both automatic and manual. The software platform has been developed and continually improved over 40 years of market experience. Currently, we successfully manage more than 400 automated factories and distribution centers, offering an end-to-end portfolio, enabling us to automate all the processes within a Distribution Center, guaranteeing overall technical assistance during the full life cycle of the systems. A distinctive element of E80 Group's portfolio are our laser-guided vehicle systems (LGVs), capable of performing all typical operations of manual forklifts but in a tracked, safe, and efficient way. Solutions based on LGV technology ensure fast and straightforward automation of existing DCs (brownfields) as they maximize our customers' pre-existing infrastructure, with targeted improvements to elevate performance and safety standards.Looking ahead, our future involves further portfolio expansion for integrated solutions, with fully automatic case picking systems, capable of reducing or eliminating the use of traditional package transport and sorters, offering tangible and immediate benefits in terms of flexibility, scalability, and bottleneck minimization.

E80 Group offers a solid reference point in the field of intralogistics: in addition to designing and implementing automated solutions and integrated systems, we offer highly specialized consulting, powered by cutting-edge simulation software which allows the optimization of the customer’s processes even before the systems are implemented, with a 95% reliability. Our strategic and customized support provides companies with 24/7 service, both digitally and directly on-site. Our expertise is the result of shared experience and know-how, accrued both in-house and externally. These customer-centric skills allow us to accompany our customers on the path of digital transformation, ensuring lasting success in an increasingly competitive market.

Read the business success story of PreGel logistics center 4.0, in Italy.